Battery Recycling Innovation Park

A fast growing battery industry ecosystem at Ylivieska region offering a lot of business opportunities and an opportunity to change the world through new battery and recycling technologies.

Branch: Production technology

Duration: 1.1.2020 -30.6.2023

Region: North Ostrobothnia

Financed by: European Regional Development Fund, Council of Oulu Region

Battery Recycling Innovation Park is a project funded by the European Regional Development Fund (ERDF), and it was launched in May 2020. The aim of the project is to create a battery industry innovation park in Ylivieska focusing on lithium-ion battery recycling innovations and the circular economy. Key research and development areas include battery testing and condition assessment, battery handling process automation, robotics, application of Industry4.0 solutions, development of various simulations and virtual testing environment (pilot plant), security and logistics solutions, ICT applications, etc. The project is managed by the City of Ylivieska, Centria University of Applied Sciences and Sievi Industry Park Ltd.

Battery Recycling Innovation Park focuses on battery recycling technologies and the circular economy. We aim at creating a battery recycling industry innovation and circular economy park in Ylivieska and a related network of companies and partners. We have identified interested start-ups, SMEs, large companies and R&D actors across Europe, and currently around 50 companies have now confirmed their participation in our network. About half of the companies are from abroad and another half from Finland.

WP 01 Battery Recycling Innovation Park Development Steps (Ytek)

6-step model rotation: Repetition of a specificative round during second year from step 1 to step 6

Step 1: Mapping synergies between innovation park partners

Step 2: Creating a common vision for the park

Step 3: Building a network between companies and other partners

Step 4: Creating a business model

Step 5: Creating a strategy for Invest-In activities

Step 6: Piloting new business models and enabling activities

WP 02 Mapping of The Residual Resource Material Flows And Usability Cases (Centria)

Task 1: Materials mapping

- Mapping and characterization of material flows from batteries including

A) potential recycling materials

B) potential residual capacity - Methods: Literature, research findings, laboratory analysis at Centria premises

Task 2: Mapping of industry digitalization (industry 4.0) application opportunities in battery recycling process

- Benefitting from the newest laboratory investments in making demonstrations, mapping development environment needs and future technologies from the battery recycling point of view

- Study of current and forthcoming production technology applications in battery recycling process

- Robot and cobot applications, machine vision and other identification technologies (RFID, 2D-barcodes) as the most pivotal field or research

- Research on the latest and future identification technologies such as 2D and 3D identification, transillumination technologies and various mobile robot applications for automatic identification of integrated and/or crushed batteries

- Developing automated disassembly lines

- The role of artificial intelligence and machine learning in the interpretation of identification data. A research partition will be carried out related to future application opportunities of these technologies in battery recycling industry

- Exploration of new technologies such as digital twins in battery recycling plants and circular economy environment in order to

- Generate data on e.g. battery types, failure situations and different states of the processes for the requirements of Battery Management Systems

- To develop processes and simulation models in production plants and to generate an advantageous environment for integrated and comprehensive process optimation

- To improve remote controlling and remote configuration capabilities at the plants and of the whole recycling network

Safety

- Drone applications for enabling safety of the processing and working areas will be examined

- Dust, overheating and gasification of battery materials during transportation, warehousing and processing constitute a significant risk in battery recycling process thus generating a risk of fires and explosions

- Clean air is also important from the personnel working environment point of view

- A mapping of IoT solutions in controlling processing and warehouse surroundings will be conducted through gas, dust and temperature sensors including thermographic cameras and optical probes

- Mobile robots’ and drones’ role in increasing the safety of high-quality measurements in the processing environment will also be studied

- A study of battery logistics chains will be implemented through Industry 4.0. applications related for instance to controlling battery recycling bins becoming overfilled, which in turn creates safety hazards for the environment

Task 3: Recycling Material Flows

Task 3 will be implemented based on the results from the composition and residual capacity data from WP2

- The aim is to examine residual material capacities of current battery types as well as of batteries manufactured by latest battery manufacturing technologies. This will comprise:

- recycling capabilities

- reutilization capabilities

- creation of a feasible value chain model through which the preservation of the materials’ value can be verified for as long as possible

- Totally new and potential alternative uses as well as reutilization of battery materials will be taken into account

- A comparison between battery recycling and reutilization models already in general use and their applicability for the purposes of a recycling innovation park environment will be implemented

WP 03 Biocarbon And Graphite in Battery Industry (Sievi Industry Park)

- Applicability of graphite found in biocarbon as a substituent for anode material in batteries.

- Study on the potential recycling capabilities of biocarbon applications

- Use of biocarbon based graphite in developing new battery technologies, e.g. as a raw material for salt batteries as an alternative for lithium-ion batteries

- One of the advantages of biocarbon-based materials such as graphite used in batteries is that they can be totally discharged, which means that their transportation is safer. Currently, salt batteries’ charging cycles are not long enough to compete with lithium-ion batteries, but as technologies evolve, their applications may grow significantly.

WP 04 Facilities And Equipment Planning (Ytek)

- During WP1 a circulation economy network and interest groups will be formed and following procurements are planned accordingly

- Equipment specifications will be planned taking into account the needs of the participating companies

- Equipment for research and piloting projects

- Rearrangement of current laboratory and office facilities

- Potential new facilities

WP 05 Project Coordination (Ytek)

Overall administrative coordination of the project.

The resources and services provided by the project, together with the network of companies and partners, enable the development of new business models, technologies, joint research and development projects between companies and R&D actors as well as domestic and international contacts and cooperation. We are able to provide interested companies with laboratory, testing, simulation and business facilities as well as robots and other equipment for product and service development needs. This will facilitate companies’ opportunities to develop new solutions for the battery industry, battery recycling and related energy solutions as well as in other related fields.

We are also currently exploring the possibility of implementing a recycling pilot and testing plant for li-ion batteries and a virtual development environment as part of the innovation park. A sister project, BR Pilot Plant, was launched in September 2021, and the SAAROB project for the robotic disassembly of electric car batteries at Centria University of Applied Sciences will support the emergence of new businesses and a battery cluster in the region.

Background

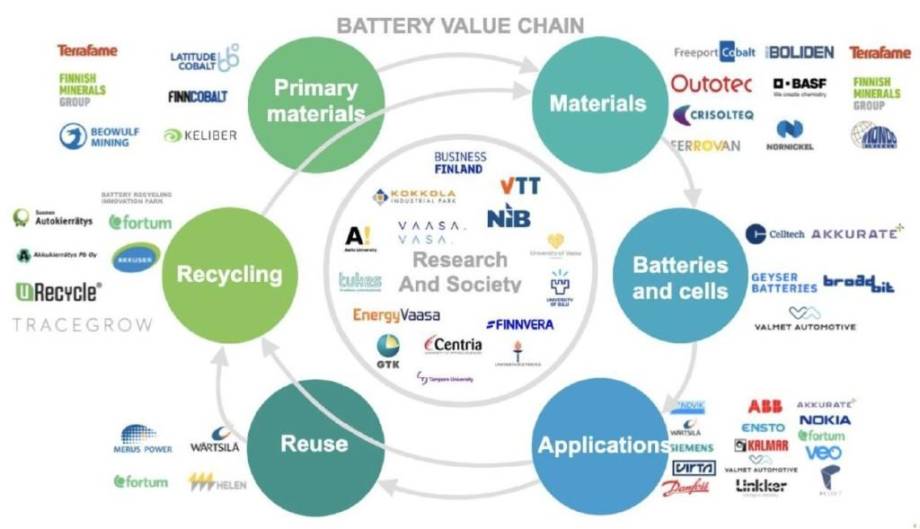

The use of batteries is driven by the growth of e-transport and renewable energy, and the value of the battery market in Europe is projected at EUR 250 billion by 2025. Finland has extensive know-how related to the battery value chain: strong mining and raw-material processing industry and technological competence in the manufacture, use and recycling of batteries. Climate change and the reduction of the carbon footprint have created a huge demand for sustainable battery recycling technologies, and Finland is aiming at becoming a leading technology and service expert in the global market.

- Robotic and machine vision applications

- XRF and optical sorting technologies

- Voltage discharge and battery testing technologies

- Battery Management System

- Battery cell second life options

- New uses for battery materials and improvement of recycling rates

- Ways to identify and recover higher concentration products in the recycling process

- Safe battery disposal and disassembly processing technologies

- Adding information on present and future battery constructions and types

- Finding the most interesting battery materials and material combinations in recyclable batteries for battery and other industries

- More efficient material recycling

- Developing material separation and recovery processes and finding the best material format

- Recycled rare metals-related intermediate products

Value structure of battery life cycle

Centria University of Applied Sciences

Centria’s research and development collaborates with companies and organizations to increase their competitiveness. Centria aims at helping companies in developing new products, business ventures and international activities and as well as in the process of entrepreneurship by using their multidisciplinary expertise.

Centria’s R&D has been identified as one of the institution’s strengths and its success has been recognized on a national scale. Centria’s strength is the unusually close links to local working life. Local business and working life have been funding about one quarter of the research and development activities.

Centria’s research and development department currently employs a staff of around 110. There are about 90 R&D projects ongoing each year. Major public financiers for R&D projects are Business Finland (the Finnish Funding for Innovation), the EU (ERDF, ESF, INTERREG and the European Commission), regional councils as well as ELY centres (Finnish Centres for Economic Development, Transport and the Environment).

Centria UAS was involved in 5 Business Finland projects, representing a financial input of 2,6 M€ and in 2019, the total volume of Centria’s R&D was 8 M€, of which outside funding accounted for 6,6 M€.

Ylivieska

Ylivieska is a growing regional centre in Northern Ostrobothnia in Finland. The City of Ylivieska and its Business Services help local companies to succeed and new companies to start up their businesses. Our aim is to support business growth and development and to help companies in creating new jobs. Ylivieska Business Services collaborate with the local business community.

Ylivieska is a centre of a market area of 100,000 people with good services and conditions for enjoyable living, self-development and versatile business activities. Its location by the national main railway and the intersection of Finnish national road 27 and trunk road 86 guarantees fast connections everywhere. Oulunsalo and Kruunupyy airports are nearby as well as Kalajoki and Kokkola ports to the Baltic sea.

Town is known as a trade centre and as an attractive car sales centre. Strong industrial branches include metal industry, electronic mechanics and mechanical timber industry.

The region as a whole is also famous for its unique concentration of manufacturing industries in the whole of Finland.

Sievi Industrial Park

Sievi Industrial Park is an organization wholly owned by the municipality of Sievi. It produces business services such as facilities, properties and counselling for businesses located in Sievi. It collaborates actively with its partners and local companies in development projects and supports businesses in their growth and development activities.

———————

Related projects

BR Pilot Plant

BR Pilot Plant project will investigate preconditions for a new type of international level production and technological testing environment (demo plant) related to the dismantling of lithium-ion batteries as a part of Ylivieska Battery Park entity. In addition, information can be obtained on other closely related topics, such as battery transport, storage and logistics issues, training needs, siting and various environmental regulations.

The immediate results of the project will support decision-making for establishing a battery recycling plant in Ylivieska. The project will also enable the emergence of a new type of industrial activity in the area. The pilot plant and the related international co-operation and circular economy will increase the number of jobs due to new and relocating companies.

In the long run, the results of the project will enable broader and more diverse growth, export and internationalization prospects for the regions’ manufacturing industry and related services, and increase the region’s overall attractiveness, dynamism, and competitiveness. The results of the project will strengthen the companies’ readiness in the Northern Ostrobothnia region to move to the next technological stage in the manufacturing industry and make the most of the opportunities offered by new processing methods and Industry 4.0 in the fast-growing battery industry in Europe and globally. Project is financed by ERDF funding from Council of Oulu Region.

SAAROB

Centria University of Applied Sciences is a strong project player in the region, with experience in joint projects between industry and educational institutions. In terms of expertise, Centria University of Applied Sciences’ solid know-how in digital factory infrastructure, robotics, cobotics and artificial intelligence applications, as well as production technologies and environmental chemistry, will support the future expertise needs of a modern battery handling plant.

The research goal of Centria’s SAAROB project is to find and utilize safe and productivity-enhancing solutions, ideas and operating models for the logistical challenges of future battery recycling through a new generation of robotics, digitalisation and intelligent automation. Project is financed by Council of Oulu Region ERDF funding. The project will create and test a robotic research, development, and innovation environment focusing on the safe reuse of battery technology and create a concept that will communicate research results to companies and actors in the form of application demonstrations, process simulations, and data packages. As a result, regional companies, actors and consumers will receive concrete research data and solutions on the process of recycling battery technology in electric cars as part of the low-carbon society of the future.

The results of the project will serve the region’s industrial companies by providing applicable information on the operating conditions of the battery recycling industry in the region, and it can also be used in the development of the region’s industries in other sectors. This information will strengthen the companies’ readiness to move to the next technological stage in the manufacturing industry and make the best possible use of e.g. the potential of new handling methods and Industry 4.0 in the battery recycling industry.

Ylivieska is a regional growth centre that is developing steadily with a projected growth rate of +18 % by 2040. The growth projection of jobs is also good: the aim is that the town will have 1000 new jobs by 2030. Ylivieska is the centre of its neighbouring municipalities and works systematically to enable the market area of up to 100 000 inhabitants to continue growing. In 2019 Ylivieska region was recognized as one of the functionally significant urban regions in Finland (MDI 2019: Urban Network Study)

Ylivieska offers great opportunities for entrepreneurs in the industrial sector and a good environment for businesses. Ylivieska has a solid industry network whose areas of expertise are utilized by many businesses and subcontracting networks in the region. By networking with other businesses in the region, you can grow your business with lower business cycle fluctuation and investment risks. Competent work force is provided by various educational institutions. Construction and construction product industry as well as metal industry are especially strong in the region.

The location of Ylivieska is one of the secrets to its growth. Travel to and from Ylivieska is easy due to its favourable location at an intersection of highways and by one of Finland’s main railway lines. This is a great advantage from the business travellers point of view: you can travel by train while working comfortably at the same time, more about VR Business Services. Central position is also favourable for fast and flexible cargo transports to and from Ylivieska. The closest port is at 50 km distance and the closest airport at 70 km distance from the city.

Facilities and Equipment

Smart Testing, Simulation and Robotics Environment

Battery Park Labs comprise several labs, testing and demonstration facilities where companies and R&D organizations can research, test and demonstrate new solutions and technologies.

Battery Park Labs comprise several laboratory and demonstration facilities where companies and R&D organizations can research, test and demonstrate new solutions and technologies.

Production Technology Lab

Centria’s production technology lab is an advanced and modern robotics research and development environment, in which applied research and development of robotics and production automation technology is carried out. The laboratories are equipped with the latest equipment and facilities related to the research area, including e.g. collaborative robots, mobile robots, industrial robots, drones, machine vision and sensor technologies, simulation VR and AR equipment, etc. Research and development priorities include collaborative robotics, machine vision, artificial intelligence, robotics safety, and agile and intelligent production environments. Robotics demonstrations can also be carried out in companies’ own production environments with mobile equipment.

Centria Production Technology Research Area

Battery Chemistry Lab

The most important part of the laboratory is a li-ion battery manufacturing line and a battery testing system in which some 48 batteries can be tested simultaneously. A speciality of the laboratory is a dry room which is essential in li-ion battery production and testing. Special equipment of the laboratory can be used to build a complete laboratory scale li-ion battery manufacturing line where batteries can be produced for research purposes. Other devices enable versatile research and testing operations of battery cells. The laboratory provides excellent opportunities for testing new battery chemicals and li-ion battery technology research and development.

Production Technology lab facilities and equipment

- Robots

- Cobots

- 3D printers

- 3D scanning

- Laser scanning

- CNC machining centre Deckel Maho 80T

- VR equipment and applications

Robots and cobots

- ABB IRB 140/IRC5

- ABB IRB 4400

- ABB IRB 6700

- Fanuc LR Mate 200iD

- KUKA KR6 R900 sixx/K C4

- Motoman MH6D/DX100

- Omron LD250 Mobile Robot

- Omron TM12

- Universal Robot UR3 cobot

Safety equipment and Safety environment

- SICK M4000 net curtain

- SICK S300

- Safety Eye

- Camera equipment

- Machine vision cameras

Virtual factory is a combination of digital and real-life simulation environment for development, research, testing and team training purposes in battery manufacturing and recycling technologies.

Real life factory processes can be miniaturized and process times accelerated in the Virtual Battery Factory. In this way complex phenomena become visible, more concrete and they can be acted upon more effectively.

Benefits:

- Industry manufacturers and other operators can test different technical solutions before investing heavily on processing lines, equipment and technologies.

- Enables faster and more efficient production process design.

- Supports higher product and process quality goals.

- Provides new opportunities for battery technology development, design and research.

- An effective way of training new and existing staff in learning to use equipment and battery plant processes.

Battery Information R&D Centre provides an unparalleled vast source of information and services related to battery recycling and wider battery industry.

These include

Publications

- Research

- Reports

- Arcticles

- Opinion pieces

Training

- Short practical courses

- Long practical and theoretical courses

- Battery Academy (local and virtual)

- Course components for partners

Consulting

- Access to our testing and research results database

- Market & Technology trends

- Industry best practise updates

R Industrial Park

The upcoming new industry hub, R Industrial Park in Ylivieska, offers companies entirely new opportunities to succeed. Recion Ltd, has long traditions in piping fabrication and strong know-how in component manufacturing and surface treatment, and will act as a leading company in the network that is currently being built. Recion’s factory in Ylivieska will become a modern business hub bringing together entrepreneurship, knowledge and skill capital in a new way to serve the needs of future commercial life and industry. Recion will be joined by new operators in the sector who will benefit from the location, Recion’s machinery and space resources, raw-material procurement, and synergies between different operators.

The industrial area will be characterised by technology industries, Industry 4.0 (i4.0) next-generation production technologies, circular economy, and battery recycling technology, among other things. The role of Centria University of Applied Sciences will become more significant, especially when it comes to adopting i4.0. The City of Ylivieska Business Services and YTEK Ylivieskan Teknologiakylä Ltd are also closely involved in the project and offer businesses a wide variety of services developing companies’ operating conditions and supporting the creation of profitable business activities and new jobs in Ylivieska, among other things.

Access to laboratory facilities will be provided on Centria UAS campus premises on Vierimaantie, Ylivieska. Industrial production space can be rented at Recion Ltd’s new R Industrial Park.

Benefits for battery park companies

- Market visibility and contacts through a vast network

- Innovative business and entrepreneurial community

- Centria University of Applied Sciences’ strong expertise in digital factory infrastructure, robotics, cobotics and artificial intelligence applications as well as in production technologies and environmental chemistry

- Opportunity to benefit from the innovation park’s international network of businesses, R&D institutions, financers and other organizations and their synergies

- Office facilities and advanced and well-equipped laboratories for testing and piloting available

- Excellent logistical connections along the main railway line, with short connections to ports in the region e.g. in Kokkola, Oulu and Kalajoki. The airports are also relatively close and the area has good road transport connections to different directions

- Proximity to strong chemical and metal industry clusters in Kokkola

- Opportunity to participate in the Battery Recycling Innovation Park future planning process

Battery recycling innovation park services

- Business services for start-ups and companies at different stages of their life cycle (e.g. networking, B2B matching service, internationalization)

- Support in hiring key people and taking care of the bureaucracy

- Information packages for companies

- Help in finding partners and networks

- Office and production space

- R&D services, facilities and equipment

- Active project partner collaboration in R&D projects, including R&D funding services and support

- Education and training services

Join the network

- An opportunity to participate in new battery and recycling technologies development and business opportunity creation

- Keliber lithium-ion mine nearby in Kaustinen is the largest lithium-ion mine in Europe

- Johnson Matthey and Freyr battery precursor manufacturing plants in Vaasa

- Terrafame multimetal mining company’s 240 million investments in a chemical refinery plant producing materials needed in battery industry

- Active cobalt mines, planning and prospecting projects in Finland

- Boliden Kokkola, Europe’s second biggest zinc producer in Kokkola

- Freeport Cobalt, Kokkola, has a comprehensive portfolio of cobalt-based chemical and catalyst applications and products for powder metallurgy and battery industries

- Umicore Finland cobalt refinery

- Several hundred million worth of preliminary investments in precursor and cathode active material plants in the nearby region and in Finland

- Akkuser and Tracegrow battery recycling technology companies

- A vast network of subcontracting and other companies of different industries in the region

- Centria UAS, active digital factory infrastructure research field

- Other supporting projects currently running and others under planning

Our network currently includes more than 50 domestic and foreign companies and R&D actors. The network enables the development of new business models, joint research and development projects between companies and R&D actors, as well as international contacts and cooperation.

Why is Battery Park worth investing in?

- The value of the European battery market is projected at 250 million euros by 2025.

- Climate change and the reduction of the carbon footprint have created a huge demand for sustainable battery recycling technologies.

- The EU has set strategic goals to create an innovative, sustainable and competitive battery ecosystem in Europe.

- Finland has extensive know-how related to the battery value chain: strong mining and raw-material processing industry and technological competence in the manufacture, use and recycling of batteries.

- Finland is aiming at becoming a leading technology and service expert in the global market and at achieving a leading position as an expert in battery recycling.

- Ylivieska Battery Park will host and support new promising startups and SMEs in the battery industry. It also provides a unique testing, demonstration and reserach environment together with a strong international network enabling new technological breakthroughs in the industry.

- Ylivieska is a suitable location for e.g. a lithium-ion battery recycling plant.

- Excellent logistic connections along Finland’s main railway line, with short connections to e.g. ports in the region in Kokkola and Oulu as well as in Kalajoki. Airports are also relatively near and the area has good road transport connections to all directions.

- Proximity to strong chemical and metal industry clusters in Kokkola.

- Johnson Matthey and Freyr li-ion battery precursor plants producing components for the battery industry are located nearby in Vaasa. There are 50+ partner companies and R&D organizations in Batterypark partner network.

- The region’s strong mining industry and related development projects support the emergence of a battery ecosystem in the area.

Finnish Business Environment Assets

- Highly educated and multilingual workforce

- Free market economy

- Transparent government, political stability

- Most stable country in the world

- Vibrant and innovative start up scene

- Advanced transport and logistics

- Reliable infrastructure

- Open and green society

- A safe and family-friendly society offering many types of support and services for families with children

- Finland is among the best of the world in many fields

New developments in battery technology are changing the way we transport and power the world and battery technology has become a highly important investment theme both globally and nationally. Ylivieska region has excellent prerequisites for becoming an important link in the Finnish battery value chain. Contact us and find out more about opportunities in the Battery Park.