Smart WPC

Development of Multi-functional Hi-tech Cellolose Based Composites for Smart Products.

Branch: Chemistry and bioeconomy

Duration: 01.01.2017 – 20.12.2019

Region: International

Financed by: European Union European Regional Development Fund, Lapland Union, Region Norrbotten

Budget: 1 005 328 EUR

Further information: Egidija Rainosalo, +358 44 7250264, egidija.rainosalo@centria.fi

Project Manager: Egidija Rainosalo

Background

The increase in environmental awareness among the public and stringent regulations from the governing bodies are the main driving forces for growing interest in biobased materials. Wood plastic composites (WPC) are comprised of wood or other cellulose-based fibre and virgin or waste plastics. This way great shear of plastics can be replaced by bio-based origin material.

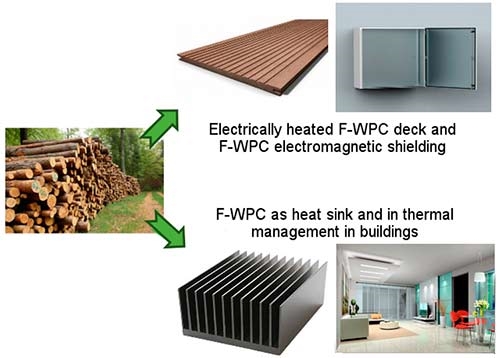

In Europe and North America, WPCs are used predominately in the building and construction sector. There is high demand from Nordic forest industry to increase the added value of forestry products. One way to improve the demand for WPC is to broaden the variety of applications by incorporating special functionalities (F-WPC), such as for example electrical conductivity, thermal conductivity, enhancing mechanical performance, and others. This will enhance WPCs performance in the applications where it is conventionally used and additionally will open new service sectors.

The target group of this project covers the whole value chain including material suppliers and producers (from forestry resources and side-streams, mining industry, and plastics including recycled plastics), composite processors and product manufacturers, end-users of composite products (from construction, transportation, and electronic industry, etc.), research organizations

and providers of knowledge transfer services.

Project is financed under the Interreg Nord programme 2014-2020 with grand assistance received through Region Norbotten and Regional Council of Lapland in Finland.

Funding:

- Overall budget of the project is 1 005 328 EUR, EU support 653 463 EUR

- Project duration 1.1.2017 – 20.12.2019

Goals

Smart WPC aims to integrate add-on functionalities in WPC by incorporating thermally and electrically conducting fillers. Improving the electrical and thermal conductivity of otherwise non-conducting WPC’s without sacrificing the mechanical properties will open more application sectors. Another objective of the project is to develop manufacturing technologies to produce hybrid F-WPC with improved structural properties, Continuous cellulose fibre will be utilised as reinforcement for this purpose.

The project will fill the knowledge and technological gap that prevent the use of commercialised bio-based materials in functional and highly required structural applications in various industrial sectors. The targeted SMEs and industries are located geographically in northern Sweden and northern Finland.

Applications

Heat dissipation is a critical factor governing the performance, lifespan, and consistency of electronic devices. The emergence of new applications such as light emitting diodes (LED) and functionalization of electronics made the thermal dissipation a challenging issue. Aluminium alloys are generally used to control the higher heat fluxes in electronics. According to the leading conductive plastic manufacturers, the higher thermal conductivity of metals cannot be effectively utilised if the conduction of heat to the surface of material is faster than the air-flow convection removing the heat from source. Thus the thermally conductive plastics are suitable in applications where convection is a limiting factor. Other driving factors to use thermally conductive WPC are light weight and ease of processing when compared to metals.

F-WPC can be utilised not only in the thermal management of electronics but also in the thermal management of buildings. This can be achieved by incorporating suitable materials that control the temperature in the F-WPC with improved thermal conductivity.

WPCs are primarily used as decking. Integration of F-WPC with continuous cellulose fibre will enable the production of electrically heated decking without sacrificing the structural properties. It is expected to be value-added property in decking materials and will stimulate wider use of WPC. Electrically functional WPC is also assumed to find its application as electromagnetic shielding and as electrostatic discharge material (ESD).

The project partners

Centria University of Applied Sciences

Dr. Tech. Egidija Rainosalo

Project Manager

+358 44 7250264

egidija.rainosalo@centria.fi

Luleå University of Technology

Prof. Roberts Joffe

+46 920 491 940

roberts.joffe@ltu.se

Swerea SICOMP

Ph.D. Guan Gong

+46 911 74416

guan.gong@swerea.se