PlastLab – Material development and 3D printing

Centria has extensive expertise in plastic and composite materials, which extends from the selection and manufacturing of materials to the 3D printing of products.

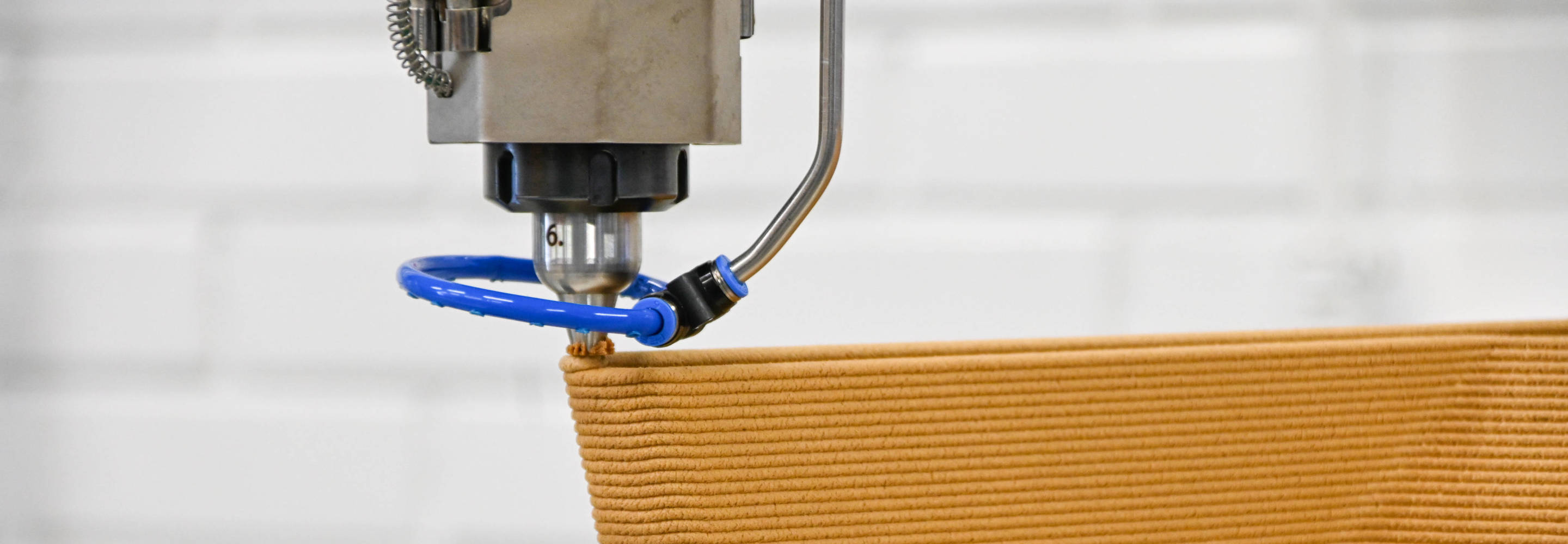

3D printing as a production method

The versatile possibilities of 3D printing have made it one of the most interesting production methods. With 3D printing, you can easily produce a digitally designed model into a physical piece. There is usually little waste, and the product’s carbon footprint can be smaller compared to traditional forms of production. By printing, you can produce e.g. various utility objects, moulds or parts needed by different industries. Current printing materials include various biocomposites, where added natural fibres reduce the need for fossil oil and at the same time improve the plastic’s strength, dimensional stability and recyclability.

At PlastLab, our experts manufacture various biocomposites and study the mechanical properties of the materials, such as tensile strength or resistance to weather, for example, temperature and humidity. The premises can be used to produce filament for traditional 3D printing or produce products directly from plastic pellets with a 3D printing robot.

Our experts have strong robotics and product design expertise, which can be utilized in the development of new products. PlastLab has great opportunities for companies and R&D projects to manufacture and test products from different composite materials.

Our equipment

- 3D printing robot workstation includes ABB industrial robot, 2,7 m long external linear track, two work tables: regular and rotating workpiece positioner, max 12 kg/h throughput extruder

- FDM 3D printer for printing small plastic products

- Compounder twin screw extruder for the production of plastic compounds, maximum capacity of 100 kg/day

- Hot press or preparation of plastic sheets

- Filament maker for the production of printing filament from granules or shredded plastic

- Vacuum infusion for manufacturing reinforced composite parts

- Shredder for shredding recyclable plastic products

- Tensile tester for testing the mechanical properties of materials and products

- Environmental chamber for evaluating the effects of temperature and humidity