Product development services

Centria’s product development services provide expertise to support companies in their product development and innovation phases.

From idea refinement to testing

Our product development services can help you refine your idea and help you design and conceptualise your product. We carry out a wide range of testing and measurement assignments for products and prototypes, which provide information for product development or demonstrate compliance, for example.

Our product development service package includes a wide range of possibilities for prototyping and batch production. For prototyping, we can use the equipment in our laboratories, including metalworking, woodworking and rapid modelling equipment. Our product development services also include various needs assessments, technology studies, pre-studies, and research services related to foresight.

Our product development services

EMC testing services

We take care of the EMC testing of your equipment, so you can be sure it does not introduce intolerable electromagnetic disturbance to anything in its working environment.

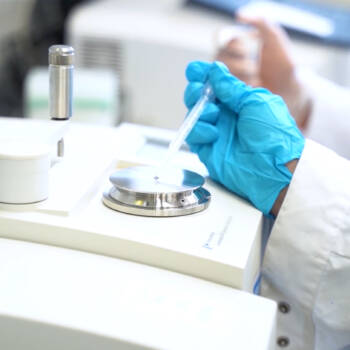

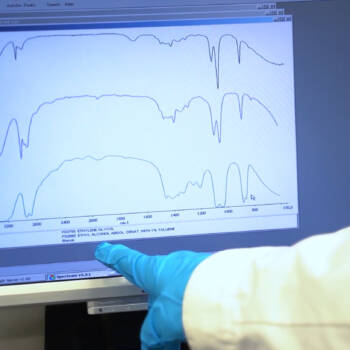

Compositional analysis service

Our compositional analysis service provides answers to various questions related to e.g. raw materials, products, and materials. We conduct analyses from the raw material all the way to the final product.

Materials Research Service

Our materials research service helps you to understand the challenges related to materials and their properties.

Software development service

We offer a software development and design service that provides individually tailored solutions to meet customers’ needs and challenges.

Climatic testing service

Tests carried out in accordance with standards provide accurate and unbiased information on the different characteristics of a product.

Door and window testing service

Unbiased testing service for the flexible and fast product development of doors and windows.

Vibration testing

Testing service for products exposed to vibration and impact. Our typical customers are manufacturers of electronics, vehicles and machinery.

Weather testing service

To support your product development, Centria offers accelerated weather testing in the QUV cabinet, as well as outdoor weather testing.

Water permeability assessment

We offer a service that allows you to assess the water permeability of a surface treatment product.

Contact

Jani Rättyä