CMT – Nordic business opportunities from coating and additive manufacturing

Interreg V A Nord is a EU-program supporting cross-border cooperation in order to strengthen the economic and social development. Areas included in the program are north Norway, north Finland, north Sweden and Sápmi (which spreads over all three countries).

Toimiala: Tuotantoteknologia

Projektin kesto: 01.05.2015 – 30.04.2018

Toiminta-alue: Kansainvälinen

Rahoittajat: European Union Interreg Nord

Budjetti: 1 465 634 EUR

Lisätiedot: Ilkka Rasehorn, +358 40 808 5105, ilkka.rasehorn@centria.fi

Projektipäällikkö: Ilkka Rasehorn

Funding

Project is funded by Interreg Nord and the total budget is 1 465 634 EUR.

Interreg V A Nord is a EU-program supporting cross-border cooperation in order to strengthen the economic and social development. Areas included in the program are north Norway, north Finland, north Sweden and Sápmi (which spreads over all three countries).

Project objectives

There are three main objectives to substitute conventional and promote high-tech manufacturing and surfacing techniques for the benefit of regions SMEs and large enterprises:

- Finding a new innovative and cost efficient ways of producing coatings

- New additive manufacturing solutions provided by CMT

- Commercialization of opportunities created by CMT

Current issues

Seminar & workshop: Surface Engineering and CMT will be held at Tampere University of Technology on Wed, April 25th, 2018. Seminar deals with the results of the project and is free of charge.

Seminar poster: Surface Engineering and CMT

Project partners

Centria University of Applied Sciences, Kokkola Finland

Tampere University of Technology, TUT, Tampere Finland

Lulea University of Technology, LTU, Luleå Sweden

The Arctic University of Norway, UiT, Tromsø Norway

Contact

Centria, Finland: Ilkka Rasehorn, ilkka.rasehorn@centria.fi, +358 40 808 5105

TUT, Finland: Jari Tuominen, jari.tuominen@tut.fi, +358 40 849 0196

LTU, Sweden: Torbjörn Ilar, torbjorn.ilar@ltu.se, +46 92 049 1679

UiT, Norway: Abbas Barabadi, abbas.b.abadi@uit.no, +47 77 660 339

CMT Process

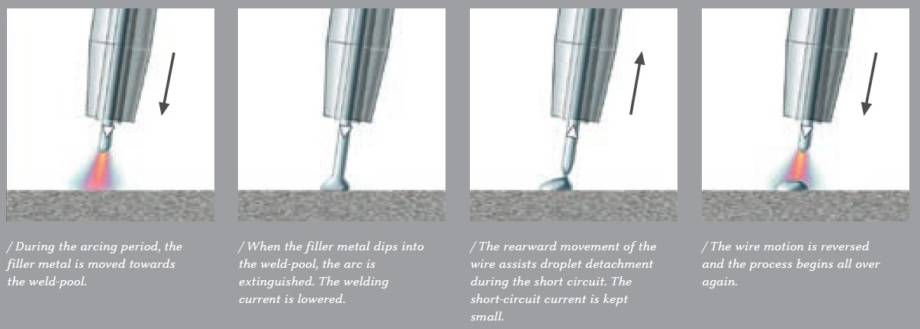

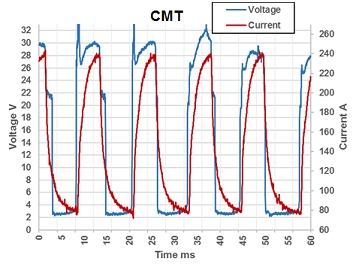

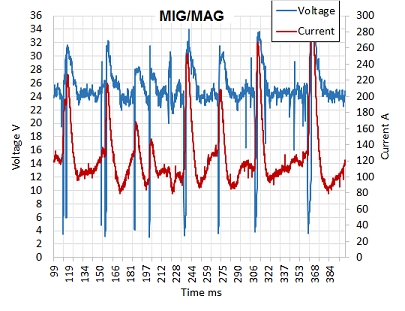

CMT – Cold Metal Transfer is MIG/MAG arc welding process developed by Austrian welding power source manufacturer Fronius GmbH.

Charasteristic features for process are:

- Pulsed and controlled waveform voltage and current.

- Welding filler wire is drawn backwards, syncronized with voltage and current, with a frequency of 70 – 80 Hz.

Benefits of process include:

- Spatter free welding

- Low heat input to the base material

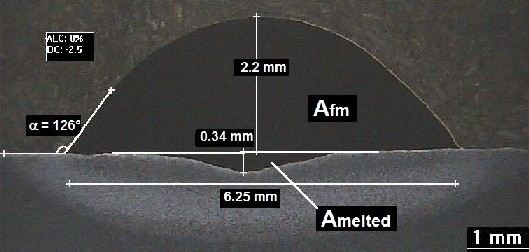

Especially low heat input makes CMT ideal process on overlay welding and additive manufacturing, since penetration and dilution can be kept on very low level.

Cross section of CMT single bead overlay weld. Low penetration (~0,3 mm) and dilution (~5%). Welding speed: 1000 mm/min, heat input: 180 J/mm, deposition rate: ~5kg/h.